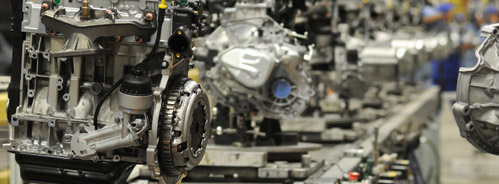

KPMC designs and engineers green sand patterns for ferrous and non-ferrous metal castings. Our innovative tooling specialties include green sand patterns for complex foundry and manufacturer applications including vertically or horizontally molded castings and both non-cored and highly-cored designs. Our solutions include tooling for aluminum, iron, and steel castings for automotive, truck, heavy industrial equipment, agricultural machinery, military and other advanced manufacturers of complex, high performance products.

Green Sand Tooling Process and Casting Specifications

Processes

· Green Sand Casting Processes

· Green Sand

· Green Sand with Sand Cores

· Green Sand with Chills

Alloys/Metals

· Aluminum

· Iron

· Grey Iron

· Ductile Iron

· Compacted Graphite Iron

· Steel

· Stainless Steel

Castings Range:

· Ounces to 50,000 lb. Castings

Industries Served:

Automotive, Trucking, Heavy Equipment, Agricultural Machinery, Military

Green Sand Tooling Advantages

· Excellent Flexibility in Choice of Molds and Patterns

· Fast, Cost-Efficient Casting Process

· Environmentally Friendly: Mold Aggregate can be Treated and Re-Used

About Green Sand Casting

The term “green sand” is known principally because of the moisture content within the sand. The sand undergoes a “mulling” process in which various clay and chemical additives that act as binders are blended with the sand, which results in a compound which is suitable for the sand molding process. This prepared sand mixture is then compressed around the pattern at specific pressures and temperatures, to ensure it will maintain its shape throughout the remainder of the casting process. The blended sand and binders are compacted around the pattern, taking on the shape of the desired casting. Sometimes the design of the casting entails internal passageways being formed into the mold. This is done by using sand cores, which are made of a similar sand mixture. The cores are strategically placed to form the necessary passageways in the casting. The two halves of the mold are subsequently closed and metal is poured into the cavity and left to solidify. After solidification has taken place, the sand is vibrated until it is released from the casting. The finishing process can then be completed by grinding, machining, plating and painting.

Specifications